choose this expertise?

Looking to:

- Validate the resistance of a product or material under extreme conditions (pressure, load, etc.).

- Gain detailed insight into failure behavior through simultaneous data collection (pressure, strain, temperature, acoustic event localization, etc.).

- Correlate measurements and refine multiphysics models to predict product performance in service.

- Optimize design and materials by precisely identifying critical zones and influential parameters.

- Secure market release with robust experimental proof.

Our customized services

Burst or cycling test up to 2000 bar

Multi-physics instrumentation (strain gauges, cameras, acoustic sensors)

Failure analysis and technical recommendations

Service Details

Burst and Cycling Tests

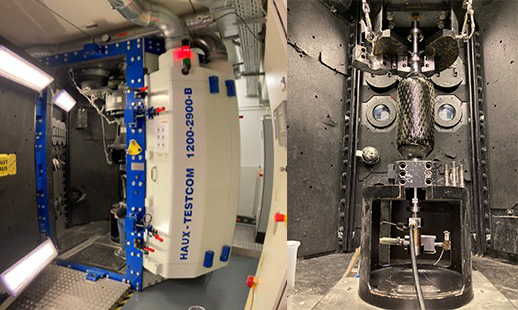

Our burst test facility allows hydraulic tests up to 2000 bar on tanks up to 1600 mm (vertical mounting). We perform both burst and cycling tests in compliance with R134 regulation, with controlled pressurization and real-time monitoring.

Objective: Validate the performance of pressure vessels, observe failure modes, and qualify your products.

Multi-Physics Instrumentation

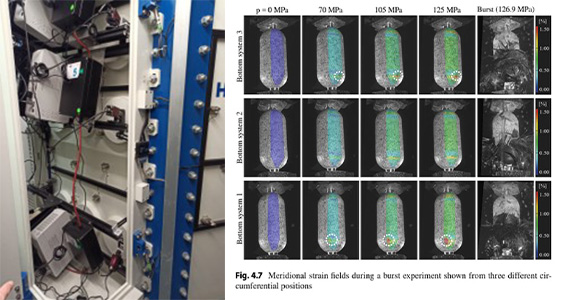

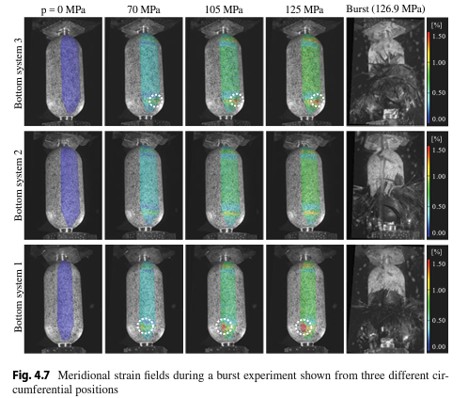

To enhance the analysis, we use advanced instrumentation: strain gauges, 9 stereo image correlation systems, 120 integrated acoustic emission microphones, piezoelectric sensors, and cameras (with a high-speed camera coming soon). This approach enables detailed monitoring of the mechanical behavior of the tank and localization of damage prior to rupture.

Objective: Gain precise understanding of damage mechanisms, both inside and on the surface.

Analysis of Results & Recommendations

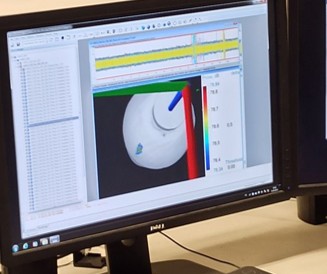

At the conclusion of the tests, we carry out a comprehensive analysis of the results: processing and cross-referencing data from sensors, correlating with simulations, and identifying critical zones and causes of failure. We provide concrete recommendations on design, material selection, or manufacturing processes.

Objective: Turn each test into a lever for optimization and reliability enhancement for your developments.

Our added value

- A complete development and manufacturing chain, from material to final testing

- Multi-instrumented tests for in-depth understanding of your products

- Ability to adapt our facilities to your experimental requirements (we can integrate your measurement tools)

- High responsiveness and tailor-made support

- Advanced modeling tools and recognized scientific expertise to support your understanding

Technical means

Equipment

Burst cell up to 2000 bars

Burning and testing equipment (radiography, porosity measurement, etc.)

9 stereo image correlation systems.

The stereo correlation cameras are located next to the acoustic emission sensors, and the acquisition image shows the results of both systems.

120 acoustic emission sensors distributed throughout the chamber.

And also

- Curing and testing equipment: X-rays, porosity measurement, etc.

- Laser gauges and high-precision instrumentation

- High-speed camera

Software

Image reconstruction scripts:

Strain field analysis