choose this expertise?

Looking to:

- Prototype parts to test and optimize your design?

- Convert a thermoset (TS) composite part into a thermoplastic (TP) version?

- Optimize process parameters to gain both in quality and productivity?

- Evaluate these processes before investing in machines?

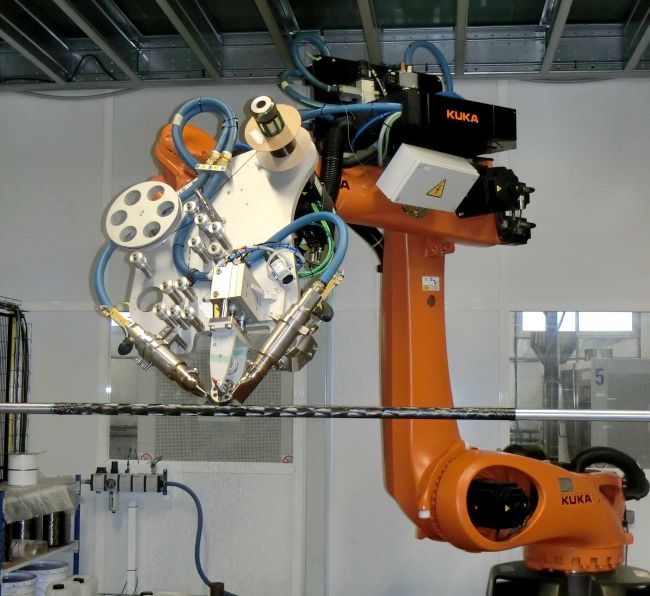

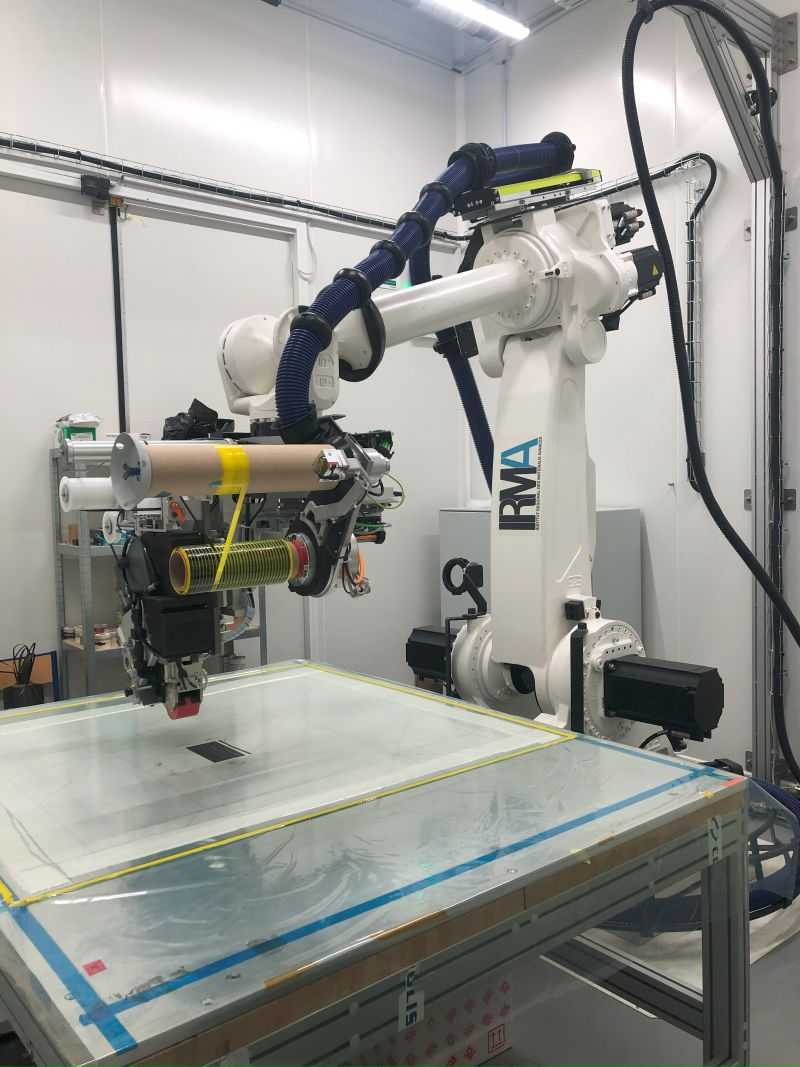

We operate a complete range of AFP and filament winding machines:

- Coriolis C1.1 AFP with horizontal-axis positioner, IR and Laser heating – ideal for industrializing complex-shaped parts.

- Coriolis C-Solo AFP with IR and Laser heating – for testing new materials, prototypes, and demonstrators.

- Addcomposites AFP-XS – tailored to SME applications, easy to program and operate.

- Filament Winding Machines – 3-spindle thermoset version and 1-spindle thermoplastic R&D version, for manufacturing revolution parts (tubes, tanks, pressure vessels).

Les experts composites et procédés de UBSIDE lèvent vos verrous technologiques et industriels. Ils accompagnent votre projet de la définition de la pièce fabricable par ces moyens à l’achat de machines ou au choix de partenaires fabricants.

Choosing automated manufacturing such as AFP or filament winding means gaining:

- High precision in fiber placement and repeatability, ensuring consistent quality.

- The ability to define fiber orientation tape by tape, optimizing both the part’s strength and weight.

Compatibility with a wide range of fibers (glass, carbon, Kevlar, natural fibers, etc.) and both thermoset and thermoplastic resins.

Our customized services

Layup and winding program development

Testing of new tapes or towpregs

Prototype and Industrial Demonstrator Manufacturing

Pre-series and small-batch production

Expert Feedback and Consulting

Industrialization strategy

Service Details

Layup and winding program development

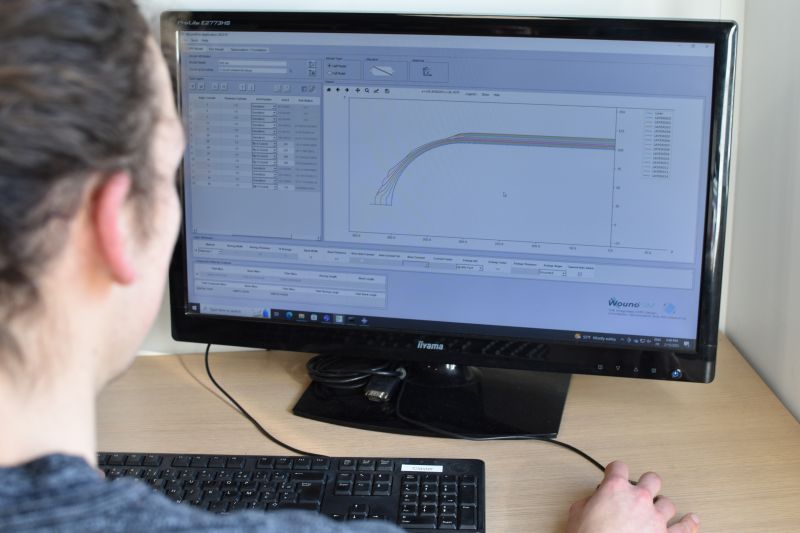

Starting from your CAD model and load specifications, we design the optimal layup plan achievable with the chosen machine. Simulation with Simulia (Abaqus) or Woundsim (S-Vertical) ensures validation of fiber paths and compatibility with the process.

Programming with CADFIBER (Coriolis), AddPath (Addcomposites), and our proprietary winding plande software.

Testing of new tapes or towpregs

For years, we have been evaluating commercial tapes and towpregs as well as those under development from material suppliers. We have established standardized testing protocols: layup strategies on the C-Solo machine for extracting characterization specimens, as well as ring (NOL) and test plates produced by filament winding.

UBSIDE optimizes process parameters by manufacturing test plates or tubes. We define procedures to achieve maximum material properties, including material reference, heating temperature, winding/layup speed, roller pressure, and towpreg tension. Our teams deliver documented analyses of different material/process combinations, including datasheets for the recommended materials and processes, along with multi-criteria comparisons.

Prototype and Industrial Demonstrator Manufacturing & Small-Series / Pre-Series Production

Do you want to entrust us with the design, programming, and manufacturing of your part?

We take care of everything.

Would you prefer to operate the machine with close support? We train your team and provide assistance throughout the manufacturing process.

Are you already an expert in these manufacturing technologies and simply want to produce a part you have designed? We offer machine rental in a private workspace, with on-call support from our specialists.

Industrialization Proposals & Strategy: Design Optimization, Path Planning, Machine Manufacturer Consultation, Partner Selection, and Supply Chain Reliability

Producing a single part versus dozens or even hundreds requires a very different level of effort. We help you take this step by suggesting design or programming modifications that make your part easier to manufacture.

We also optimize deposition parameters to reduce unnecessary movements, shorten cycle times, and minimize the consumption of costly materials.

We can recommend reliable process providers, potential subcontractors for your production, as well as trustworthy material suppliers capable of supporting you at larger volumes.

UBSIDE can also work directly on your machines to support your skills development and production, provided our experts are familiar with your equipment.

Our added value

10+ years of expertise in developing critical and complex composite parts for aerospace, defense, competitive sailing, and hydrogen storage. Proven track record in automating the manufacturing of foils and structural thermoplastic parts in collaboration with ComposiTIC (Université Bretagne Sud). In-depth knowledge of process optimization: heating temperature, deposition speed, winding speed, roller pressure, and fiber tension. Documented multi-criteria material-process comparisons, including datasheets and recommended process parameters.

Pressure vessels design

In recent years, UBSIDE and the ComposiTIC university platform have acquired real expertise in filament winding for type IV tanks and containers subjected to high negative pressures. Our experts produce tubes, rings and plates to evaluate the properties of fibres, tow pregs and windings, and manufacture prototype tanks using commercial or R&D materials on liners supplied by our customers or injection/extrusion blow moulding partners. The prototypes can then be cycled or burst on the University of South Brittany ‘s highly instrumented burst testing facility.

Technical means

Woundsim

TS filament winding

TP filament winding

C-Solo, C1 and AFP-XS