choose this expertise?

Looking to:

- Instrument your forming, welding, and additive manufacturing processes?

- Numerically reproduce your process in terms of thermal, mechanical, and metallurgical aspects to reduce testing costs without stopping production lines?

UBSIDE supports you in selecting sensors, determining their placement, integrating them, and acquiring process in collaboration with your teams. Our experts model your processes using software such as Comsol Multiphysics® and Abaqus.

Our customized services

Process diagnostics

Propose suitable instrumentation and test plan

Instrumentation and test execution or client support

Modeling and simulation of the process

Interpretation of test and/or simulation results

Service Details

Process diagnostics

Before instrumenting a process, we perform a process diagnostic to identify the key operational parameters that affect the quality of products or parts. This allows us to propose appropriate instrumentation, which we can either install or help you optimize and configure from the existing instrumentation.

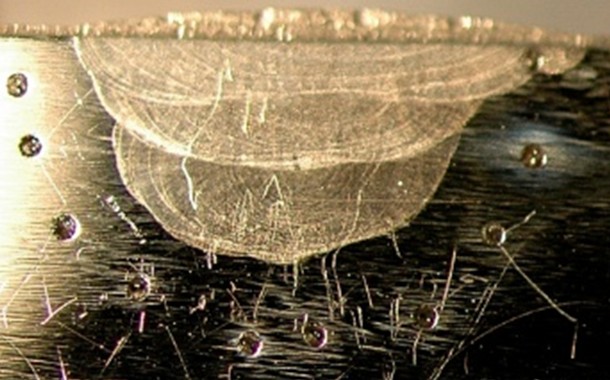

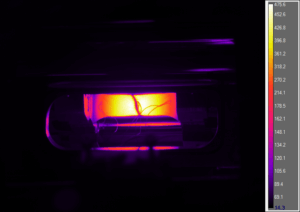

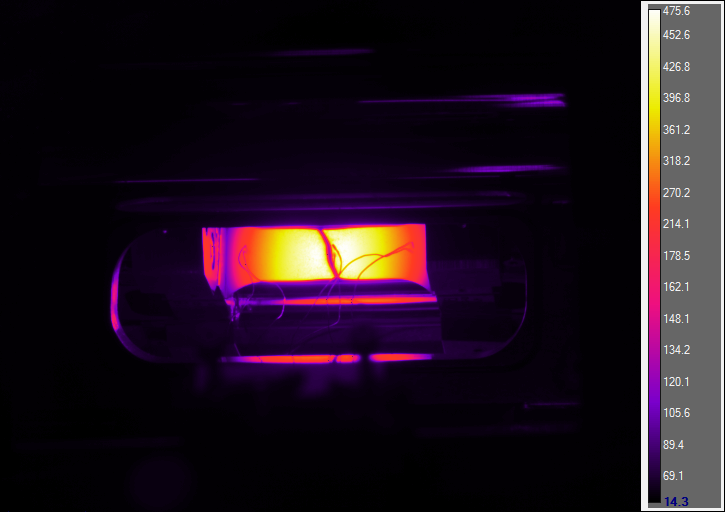

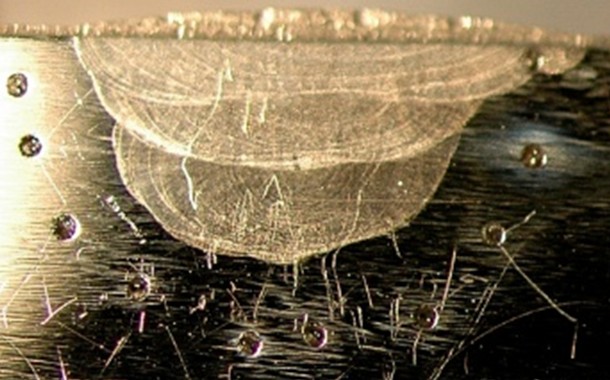

Instrumentation of parts or processes

We instrument parts or processes to obtain data relevant for process studies or quality control. Sensor placement is carefully chosen to capture information necessary for process understanding and/or development of numerical models. To minimize the impact of instrumentation, non-contact measurements can be performed, as well as precise instrumentation with thermocouples to provide more accurate data thanks to reduced response times and minimal intrusion.

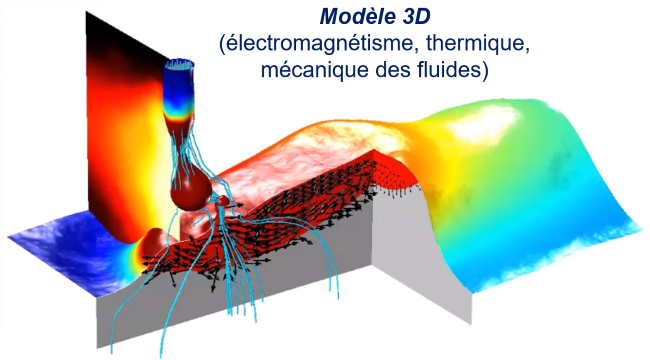

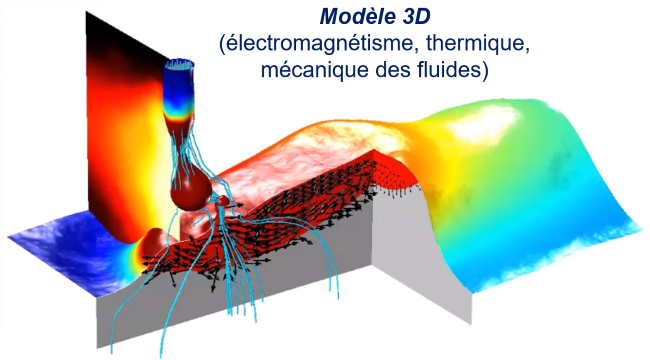

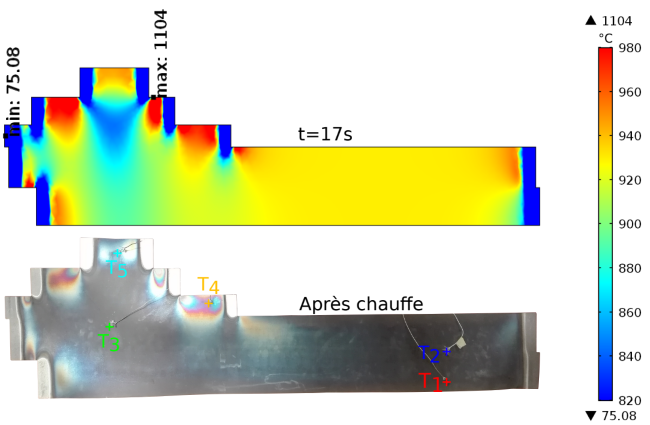

3D Part and Process Simulation

To better understand the thermal, mechanical, and metallurgical phenomena occurring during welding, additive manufacturing, and forming processes, we rely on the expertise of IRDL and software such as Abaqus and Comsol Multiphysics®. This approach prevents long production stoppages and identifies the key parameters affecting part quality. It also allows estimation of physical quantities that are otherwise inaccessible due to unsuitable or costly equipment, or impractical measurement locations, using simplified numerical models.

Our added value

Choosing UBSIDE gives you access to a comprehensive set of expertise supported by the capabilities of IRDL (Institut de Recherche Dupuy de Lôme). Our experts in thermal sciences, solid mechanics, and metallurgy enable a complete analysis of processes, combining tailored instrumentation and numerical models that reproduce part behavior.

Technical means

Thermal cameras

(640×8 to 640×512 px, 114–4243 Hz, up to 1500 °C and beyond)

Monochromatic and bichromatic pyrometers

(up to 2000 °C)

High-speed cameras

(1024×1024 px, 7500 Hz)

Thermocouples

(minimum diameter 50 µm)

Data acquisition systems

(up to 100,000 Hz)