choose this expertise?

Are you looking to:

- Evaluate raw materials (fibers, resins, prepregs), test specimens, or finished parts to verify compliance with your requirements?

- Measure mechanical or chemical properties, thermal behavior, and obtain a complete test report with analysis of results?

- Compare different materials through standardized tests to guide your design choices?

- Identify and understand failures or malfunctions in a composite part?

UBSIDE supports you from initial assessment to implementation.

Our experts advise you on the most relevant tests, testing parameters, and applicable standards. After the tests, our team guides you in interpreting the results and defining the next steps.

Our customized services

Test Selection

Test Execution

Standard Adaptation or Custom Testing

Service Details

Test Selection Based on Your Needs

A multitude of standardized and customized tests can be performed depending on your product. UBSIDE helps you determine the appropriate tests to implement your material roadmap and ensure your product meets all technical and regulatory requirements.

Execution of Standardized or Non-Standard Tests with Result Interpretation

UBSIDE ensures rapid responsiveness: we adapt our timelines to your constraints to help you save time.

Our teams assist you in analyzing and interpreting your test results, identifying improvement opportunities, and supporting decision-making.

All tests are carried out according to current international standards (ISO, EN, ASTM, …).

Implementation

- Manufacturing of resin plates

- Manufacturing of composite plates and NOL rings using automated fiber placement (AFP or EF) processes

- Production of plastic/composite parts using 3D printing

Sample Preparation Before Testing

- Specimen cutting

- Specimen conditioning (thermo-hygrometric, acid/base baths, etc.)

- Specimen instrumentation (strain gauges)

Mechanical characterization

|

|

Essais mécaniques

|

Normes associées

|

|---|---|---|

|

BENDING |

3-point bending for composite(-60 à 200°C) |

ISO14125 |

|

TENSILE |

Tensile test for composite (-60 à 200°C) |

ISO527/ASTM D3039 |

|

COMPRESSION |

Compression for composite (-60 à 200°C) |

ISO14126 |

|

SHEAR |

In-plane shear strength for composite (-60 à 200°C) |

ISO14129 |

|

CRACKING |

Cracking for composite G1C/G2C (-60 à 200°C) |

ASTM D5528 => G1C |

|

FATIGUE |

Fatigue tests for resin and composite |

Depending on the type of test |

Physicochemical characterisation

|

Essais physico-chimiques

|

Normes associées

|

|---|---|

|

Density / Porosity |

ISO1183 |

|

Composite fibre content |

Carbon: EN2564 |

|

Properties evaluation by DSC |

Carbon: EN2564 |

|

Properties evaluation by DMA |

Carbon: EN2564 |

|

Properties evaluation by TGA |

ISO11358 |

|

Polymer rheology |

Depending on the type of test |

|

Resin rheology |

Depending on the type of test |

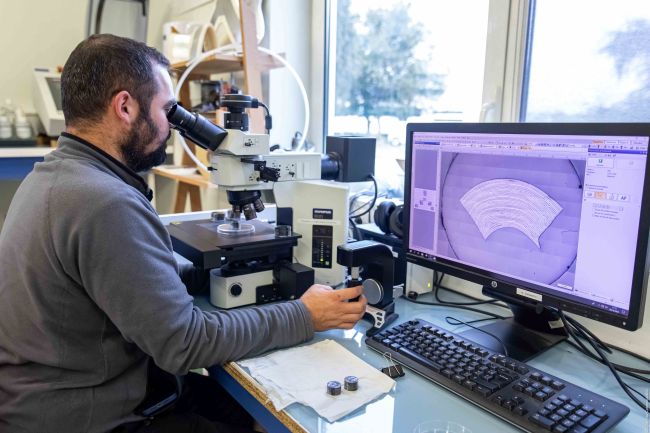

Morphological Characterization

- Microscopic observations (optical microscopy / SEM)

- Component identification via EDX analysis

- Material health monitoring (porosity, fiber content, ply thickness, etc.)

Adaptation of Standards or Custom Testing

Would you like to go further or adapt the tests to your own internal standards?

Our team of experts is here to support you by adjusting test parameters or designing a fully customized protocol and equipment, perfectly tailored to your product and objectives.

Our added value

Choosing UBSIDE means relying on an expert team capable of specifying the most relevant tests and interpreting results in light of the materials and processes used. We go beyond delivering raw data: we help you understand, challenge, and maximize the value of your results — even recommending adjustments to tests or to the product itself. Our approach is collaborative, agile, and solution-oriented.

It also means choosing tailored support that adapts to your deadlines and remains flexible with respect to both normative and specific requirements. We strive to answer your most critical questions: Is my part compliant? Is my process reliable and repeatable? Are the data used for my design calculations accurate? Has my material expired, or is it still valid for use?

Technical means

Static or dynamic mechanical testing machines with capacities from 50 N to 500 kN

Optical microscopy / SEM / EDX

Permeability measurement equipment

Thermal analysis equipment (TGA, DSC, DMA)