choose this expertise?

Looking to:

- Keep up with new plastics available on the market,

- Select the right material depending on the expected service life of your product,

- Develop a new range of materials from high-performance polymers that are heat-resistant, bio-based, biodegradable, or recycled,

- Integrate a micronized by-product into a plastic matrix,

- Design a new material with a controlled lifetime in marine environments?

UBSIDE provides support from material selection to implementation. Our experts select materials based on your technical specifications and target application, while considering both origin and end-of-life.

The formulation step, also called compounding, is a process where plastic materials are melt-blended with additives and fillers.

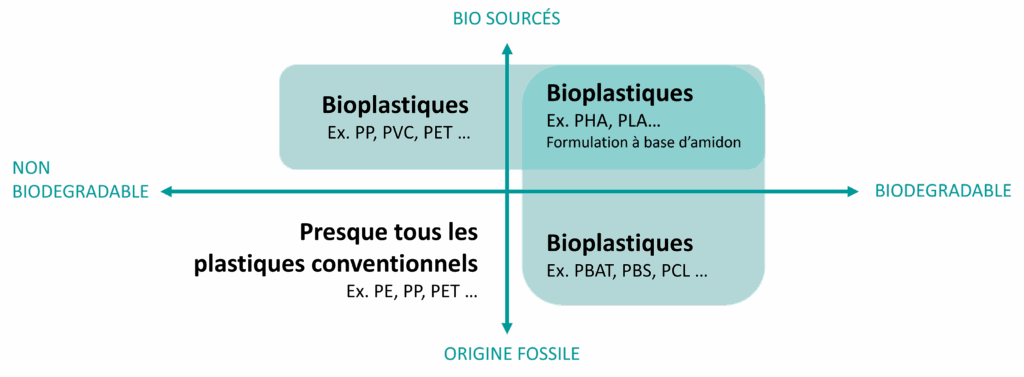

The term bioplastic refers to plastics that differ in both origin and end-of-life, and can be classified into three main polymer families:

- Bio-based and biodegradable polymers (PLA, PHA…),

- Bio-based and non-biodegradable polymers (PA 11, bioPE, bioPET…),

- Non-bio-based but biodegradable polymers (PBS, PBAT…).

What are the benefits?

- Improve mechanical properties by reinforcing the bioplastic matrix: with mineral fillers (talc, oyster shell powder…), or organic fillers (wood flour, natural fibers such as flax or jute…),

- Functionalize materials by adding additives: UV stabilization, control of degradation and/or biodegradation kinetics…

Our customized services

Targeted market watch and bibliographic study,

Needs specification and drafting of technical requirements,

Support in selecting the right material–process pair,

Development of custom granules (compounds),

Comprehensive study: from formulation to end-of-life,

Access to dedicated equipment,

Recommendation of industrial solutions.

Our added value

UBSIDE provides personalized support at every stage of polymer material development. Thanks to our expertise and technical resources, we are involved from the earliest design phases through to industrial validation.

- Extensive experience in developing functional materials adapted to different environments (terrestrial, marine…),

- Specialized know-how in marine applications, backed by a unique database of real-world feedback,

- Integrated, multidisciplinary team combining expertise in plastics processing, material chemistry, and eco-design,

- Close collaboration with your R&D, production, and quality teams to accelerate innovation.

Choosing UBSIDE means partnering with a responsive and attentive team, dedicated to transforming your innovations into concrete, sustainable industrial solutions.

Conventional implementation of polymer materials

UBSIDE offers a wide range of melt-processing techniques (injection, extrusion, thermoforming, compression molding, etc.), ensuring conventional implementation of polymer materials.

- Extrusion: production of plastic films, 3D printing filament, tubular sections, monofilaments,

- Spinning extrusion: with additional drawing module,

- Injection: production of standardized test specimens (tensile, impact…), small-batch injection,

- Thermoforming: standard test molds or custom molds,

- Compression molding: hot-plate presses.

Technical means

Depending on the material and available quantities, different machines can be used:

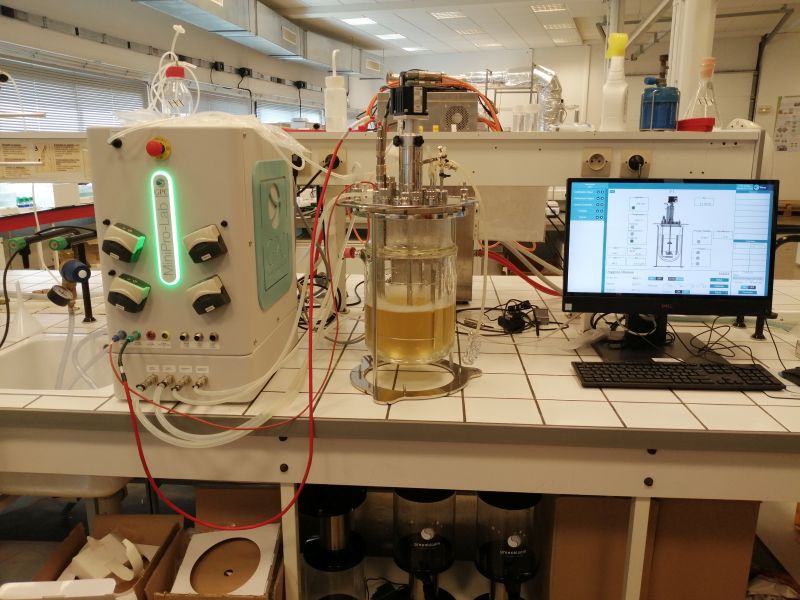

Bioreactor,

Scamex extrusion line,

Drawing machine,

Brabender,

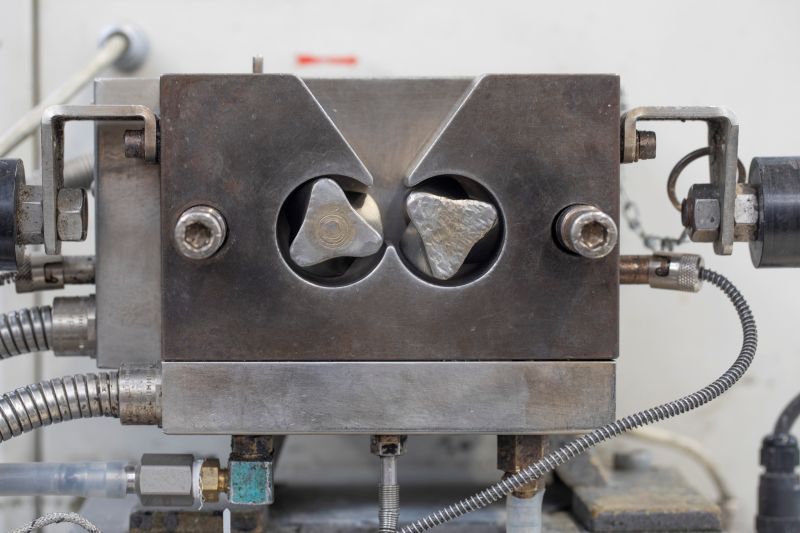

Internal mixer, counter-rotating twin-screw extruder, and co-rotating twin-screw extruder for quantities ranging from 250 g to several kilograms.

To produce new PHAs at the laboratory scale: PHA biosynthesis

Ludovic software option for simulating co-rotating twin-screw extrusion compounding