choose this expertise?

Looking to:

- Create functional, production-ready 3D printed parts – optimized through Design for Additive Manufacturing (DfAM).

- Evaluate cost savings, technical improvements, and industrial performance of 3D printing versus conventional manufacturing.

- Upgrade your existing parts using advanced composite materials and innovative processes, tailored to your business challenges.

At UBSIDE, we provide end-to-end additive manufacturing support. From design to implementation, our specialists collaborate with your teams to maximize the value of polymer and composite 3D printing for both products and manufacturing tools.

With FDM, AFP, and filament winding technologies, we ensure the right process is applied to deliver the highest impact for your projects.

Our customized services

Defining your requirements

Selecting the right 3D printing materials and processes

Functional part design

Modeling and simulation for performance optimization

Equipment recommendations and integration

Machine programming & workflow setup

Training programs for designers and 3D printing operators

Service Details

Requirements Definition for Additive Manufacturing – from consulting to complete functional and technical specifications, tailored to your 3D printing projects.

At UBSIDE, our specialists in functional analysis do more than listen: they challenge and refine your requirements to build robust specifications. We translate your applications, productivity goals, and cost constraints into clear, actionable requirements, ensuring the success of your 3D printing and additive manufacturing projects.

Material and Process Selection

We help you choose the best material–process combinations for your 3D printing and additive manufacturing projects, with a transparent analysis of benefits and limitations.

Our experts provide comprehensive, data-driven reports, including technical datasheets of recommended materials and processes, as well as multi-criteria benchmarking for the most efficient and cost-effective solution.

|

|

Compostabilité industrielle

|

Compostabilité domestique

|

Biodégradabilité en sol naturel

|

Biodégradabilité en milieu marin

|

Biodégradabilité en eau douce

|

Biodégradabilité facile

|

|---|---|---|---|---|---|---|

|

Specification standards |

NF EN 1499 |

NF T 51-800 |

NF U52-001 |

ISO 22403 |

|

OCDE 301 |

|

Analysis and testing standards |

ISO 14855-1 |

ISO 14855-1 |

ISO 14855-1 |

ASTM D7991 |

ISO 14851 |

|

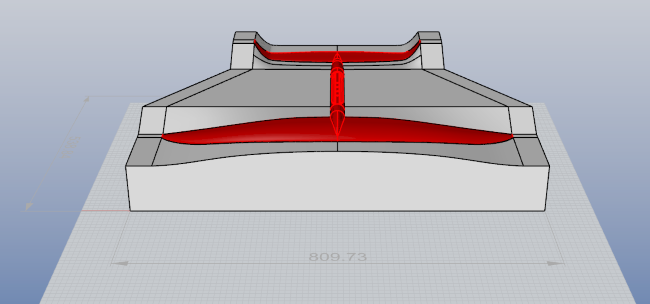

3D Part Design

From your specifications and material selection, our experts develop a 3D model optimized for additive manufacturing. Already have a CAD file? We adjust and optimize it according to the specific process requirements (FDM, AFP, filament winding) to guarantee reliable, efficient, and production-ready results.

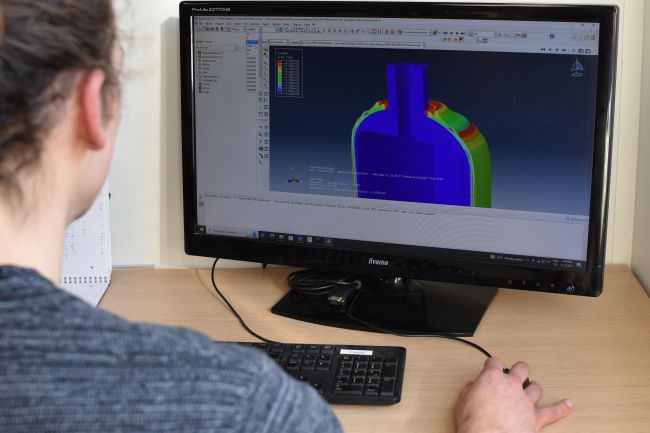

3D Part and Process Simulation

For projects requiring robustness and dimensional accuracy, we work with ComposiTIC to provide advanced 3D modeling and simulation of part performance.

To guarantee material integrity and mechanical strength, ComposiTIC runs detailed process simulations. Parameters such as heating laws, AFP deposition pressure, and filament winding tension are tested and optimized — ensuring reliable, high-performance parts.

Equipment Selection & Procurement Support

From production volumes and cycle times to scalability needs, we assess your manufacturing conditions to recommend the best-fit additive manufacturing equipment.

At UBSIDE, we also manage supplier inquiries and compile a comprehensive purchasing dossier — covering industrial 3D printers, AFP machines, and automated fiber placement systems.

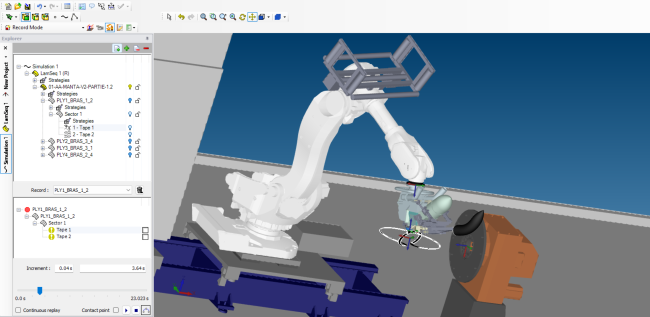

Machine Programming & Production Support

Our specialists in machine trajectories and additive manufacturing create customized printing and fiber placement programs tailored to your equipment and materials.

We ensure optimized production workflows, maximizing performance and efficiency for your 3D printing and composite manufacturing projects.

Training programs for designers and 3D printing operators

UBSIDE provides customized training programs to help your designers and operators gain expertise in 3D printing and additive manufacturing.

Our courses cover DfAM, material selection, and machine programming, enabling your teams to quickly and effectively enhance their skills and optimize production performance.

|

|

Compostabilité industrielle

|

Compostabilité domestique

|

Biodégradabilité en sol naturel

|

Biodégradabilité en milieu marin

|

Biodégradabilité en eau douce

|

Biodégradabilité facile

|

|---|---|---|---|---|---|---|

|

Specification standards |

NF EN 1499 |

NF T 51-800 |

NF U52-001 |

ISO 22403 |

|

OCDE 301 |

|

Analysis and testing standards |

ISO 14855-1 |

ISO 14855-1 |

ISO 14855-1 |

ASTM D7991 |

ISO 14851 |

|

Our added value

Choosing UBSIDE gives you access to integrated expertise in materials, additive manufacturing processes, and design. Our specialists collaborate to deliver innovative, high-value solutions tailored to your industrial and environmental challenges, leveraging collective intelligence, agility, and cutting-edge technology.

Advanced Pressure Vessel design

Through years of experience together with the academic platform ComposiTIC, UBSIDE has developed strong capabilities in the design and structural sizing of gas pressure vessels under internal pressures or external vacuums — including deep-sea containers.

We model and optimize composite lay-ups for filament winding machines, specifically for Type IV and V hydrogen tanks, and select the most suitable thermoset and thermoplastic materials for reliable and high-performance applications.

Technical means

CAD on screen

Modeling / Simulation