choose this expertise?

Are you looking to:

- Identify Additive Manufacturing (AM) materials equivalent to those currently used in your processes (injection molding, machining, etc.)

- Establish the technical performance of selected materials for your specific application

- Compare alternative materials to support decision-making

Depending on your needs, UBSIDE provides: Access to commercial materials adapted to your constraints, Tailored evaluation plans and testing procedures, both in the laboratory and under operational conditions.

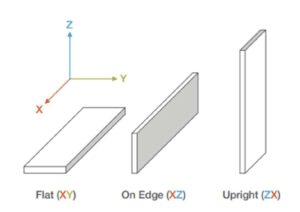

When existing materials do not meet your requirements, we define your “ideal material” and connect you with trusted formulation partners. Keep in mind that polymer and composite parts manufactured by Additive Manufacturing exhibit different mechanical, thermal, and electrical properties depending on the deposition plane and between deposited layers. Testing is conducted internally, within UBS laboratories or in collaboration with trusted partner test centers.

Our customized services

Proposals for Alternative Materials

Development of Evaluation Plans and Procedures

Recommendations of Trusted Partners

Specification of Custom Formulations

Service Details

Proposals for Alternative Materials

You contact us with your mechanical, thermal, and usage constraints, as well as your cost requirements. We then :

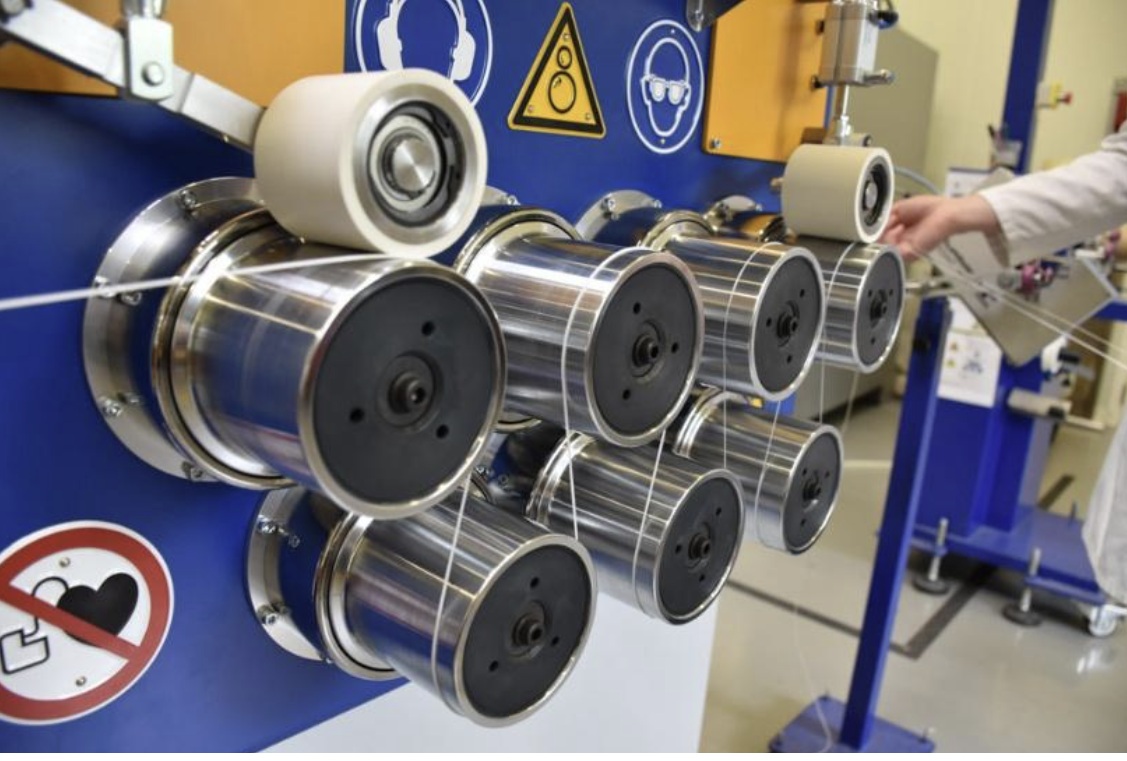

- identify one or more compatible materials capable of meeting your functional needs and processable through 3D printing, AFP (Automated Fiber Placement), or filament winding.

- Determine the unknown properties that must be validated and define the necessary testing protocols.

- Characterize materials from existing parts in order to propose commercially available alternatives.

Development of Evaluation Plans and Laboratory Testing Procedures

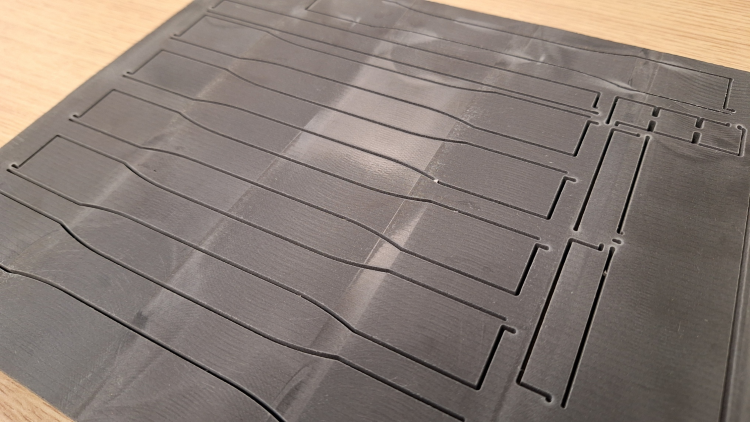

UBSIDE designs material testing plans to address missing data. These tests may involve both raw materials and 3D-printed components. The testing plan defines the necessary trials, while the procedures specify the detailed methodology, including compliance with relevant reference standards.

Example:To determine the tensile strength of a printed material in the three directions (XY, XZ, and ZX), we print plates from which the specimens are extracted. Each tensile test is carried out according to ISO 527 and requires five specimens for each selected material.

The same approach applies to thermal tests, electrical tests, and other material property evaluations.

For tests not performed in-house, UBSIDE collaborates with UBS platforms and manages subcontracting with trusted partner laboratories such as ETIM and CRT Morlaix, ensuring you benefit from a single point of contact.

Recommendations of Partners for Real-Life Testing

Before commissioning an innovative part produced by Additive Manufacturing (AM), the main challenge lies in the ability to test the component in real operating conditions—whether at sea, underwater, or in direct interaction with users—without exposing them to risk. UBSIDE can recommend trusted partners to perform such tests in specific applications. Examples include: Access to offshore racing boats to evaluate materials in competition conditions, Partnerships with Cowork’hit ( coworkhit.com) to assess assistive technologies for people with disabilities

These paid testing programs are followed by formal feedback reports and, if necessary, post-use testing to validate material and part performance under real-life conditions.

Specification of Customised Formulations

Would you like to integrate co-products from the agri-food industry or bio-based fillers into a thermoplastic resin in order to add value to a resource or achieve new material properties?

UBSIDE works with you to:

Define your material specifications

Identify the right laboratory or partner company to develop the customised granulate, filament, or tape

Whenever possible, connect you with an industrial partner capable of producing the semi-finished product at scale

We can also help you recycle your own materials, reintroducing them as semi-finished products for Additive Manufacturing (3D printing), thus enhancing both performance and sustainability.

Our added value

Choosing UBSIDE means benefiting from the expertise of materials engineers who: Master the properties of commercially available materials, Match these properties to your specific needs and applications, Understand material behaviour in Additive Manufacturing (AM), whether using granulates, 3D printing filaments, tapes, or towpregs for AFP (Automated Fiber Placement) or filament winding. For commonly used commercial materials, we have compiled material property maps to provide a clear overview of their characteristics. This enables us to support your decision-making process and feed your digital models with accurate, reliable data.

Technical means

Comparative test specimens

Scamex production line

CDI impregnation unit

Thermo-granulator:

pellets or filaments produced from recycled materials