choose this expertise?

Looking to:

- Understand the thermal, mechanical, and metallurgical properties of your materials and/or parts.

- Develop a testing procedure and/or an original characterization device.

UBSIDE can determine thermal and mechanical properties at high temperatures as well as metallurgical characteristics. We can also adapt or design methods and devices to characterize assemblies, contacts, and thermal, mechanical, and metallurgical behaviors.

Our customized services

Characterization of properties.

Development of material behavior models.

Development of customized methods and devices.

Service Details

Thermal characterization

We can determine the thermal and electrical properties of your materials at temperatures up to 1600 °C:

- Thermal and electrical conductivity, heat capacity, density, thermal diffusivity, thermal expansion

- Thermal and electrical contact resistance (TCR/ECR)

Mechanical characterization

We determine the mechanical behavior of materials from ambient temperature up to below the material’s melting point.

- Young’s modulus, mechanical strength, Poisson’s ratio, elongation at break.

- Stress-strain curves and identification of constitutive laws.

- Forming limit curves (FLC).

Metallurgy

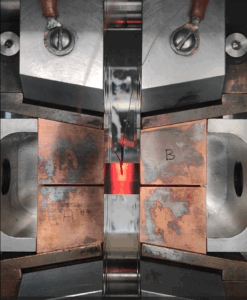

Using experimental simulations reproducing the thermo-mechanical cycles of your processes with the Gleeble 3500, we can replicate the metallurgy of your parts or determine thermo-mechanical cycles to achieve the targeted microstructure:

- Metallography/visual inspection,

- Hardness measurements,

- TTT and CCT diagrams,

- Heat treatments and mechanical loading.

Original devices and development of customized methods and devices

To meet specific requests or compensate for the lack of existing methods or devices to characterize properties or behaviors, our teams design original setups.

Examples of original devices:

- ECR/TCR measurement device up to 600 °C,

- ECR measurement during spot welding,

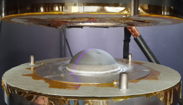

- Biaxial expansion device up to 900 °C,

- RTI (Reflectance Transformation Imaging) device for surface state characterization

Determination of properties and parameters via inverse methods

Numerical tools support the identification of your material behavior models and/or the estimation of properties through inverse methods.

Our added value

Choosing UBSIDE means benefiting from a range of expertise supported by the skills and resources of IRDL (Institut de Recherche Dupuy de Lôme). Our experts in thermal science, solid mechanics, and metallurgy guide you in selecting the most relevant properties and material behavior models to characterize, tailored to your challenges, from ambient to high temperatures.

Technical means

Thermal properties:

- Thermal conductivity meter up to 50 °C,

- Electrical conductivity meter up to 1000 °C,

- Calorimeter up to 1600 °C,

- Dilatometer up to 1000 °C,

- Thermal diffusivity meter up to 1100 °C.

Mechanical properties:

- Tensile testing machines up to 500 kN

- Sheet forming test machines

- Stereo image correlation up to 900 °C

Metallurgy:

- Gleeble 3500: tensile-compression machine with Joule heating

- Extensometers and dilatometers

- Micro and nano hardness testers

- Heat treatment with resistive furnace up to 1000 °C

- Surface analysis:

- Profilometer/roughness meter

- RTI device

- Microscope

- Dimensional measurements:

- CMM probe

- 3D scanners

Software and digital tools: Comsol Multiphysics®, Abaqus, Matlab, Python