choose this expertise?

Do you have an idea, a concept, or a design you want to turn into reality?

UBSIDE supports you at every stage with flexible additive manufacturing solutions — without any upfront investment on your side:

- Prototype to convince clients or validate your concept

- Produce pre-series or small batches, quickly and without mobilizing your resources

- Assess the industrial feasibility of your design and scale up to production

Our strength lies in a diversified 3D printing machine park, operated by experts who master process parameters and can provide you with tailored industrial solutions adapted to your materials, constraints, and performance goals.

Together with our network of trusted partners, we deliver end-to-end solutions, from prototyping to the deployment of your own additive manufacturing activity.

Our customized services

Program Optimization

Prototype and Industrial Demonstrator Manufacturing

Pre-series and small-batch production

Expert Feedback and Consulting

Industrialization strategy

Custom Finishing and Machining

Service Details

Program Optimization

Do you already have the CAD model of your part, or have you already performed initial 3D printing tests?

At UBSIDE, we take your existing files and either create new ones or optimize and adapt them to ensure they are fully compatible with your objectives, whether for prototyping, small series, or industrial production.

Our experts work with a wide range of professional CAD and 3D printing software, including Autodesk Fusion 360, Rhino, Solidworks, and Catia, allowing us to handle multiple file formats such as .step, .stl, .iges, .3mf and more.

By refining your design files and preparing them for additive manufacturing, we guarantee improved print quality, reduced errors, and better overall performance

Prototype and Industrial Demonstrator Manufacturing

To prove a concept, test an idea, or convince stakeholders, UBSIDE designs and produces prototypes tailored to your needs. Depending on your objectives, the prototype can be printed at reduced scale or full size—whether you prioritize cost-efficiency and speed, or require a highly representative model of the final product with your chosen material and custom finishes.

An industrial demonstrator also plays a key role in validating the choice of a manufacturing process, post-treatment, tooling, or machine before committing to a strategic investment.

To ensure reliability and confirm the performance of your parts, we conduct a wide range of mechanical, thermo-mechanical, and chemical tests, helping you finalize your design and accelerate your path to industrialization.

Pre-series and small-batch production

Are you in the development phase and looking to validate the design and performance of your parts?

UBSIDE takes care of producing your series with short lead times, while supporting you in making necessary adjustments between production batches.

Depending on the size, complexity, and quantity of your parts, we can also manage small batch manufacturing, offering you the flexibility to bridge the gap between prototyping and large-scale industrial production.

Expert Feedback and Consulting

With over 10 years of expertise in thermoplastic materials and additive manufacturing, our engineers share their know-how to guide you in making the right decisions.

Depending on your constraints and objectives, we provide tailored advice on:

- Material selection (cost vs. performance )

- Design optimization (print reliability and speed)

- Machine choice (from prototyping to industrial-grade systems and need for accuracy)

Already have a trained team in 3D printing? We can strengthen your workforce by working side by side with your staff, transferring our expertise directly to your machines or ours.

Proposals for industrialization: design optimizations, toolpath improvements, machine fleet adjustments, industrial partner selection, and supply chain reliability.

Proposals for industrialization: design optimizations, toolpath improvements, machine fleet adjustments, industrial partner selection, and supply chain reliability. Manufacturing a single part is not the same as producing dozens or even hundreds. We help you cross this threshold by suggesting design and programming modifications that make your parts easier to print while preventing defects and print failures.

We also optimize printing parameters to reduce unnecessary head movements and material consumption. A few minutes saved on each part quickly translate into several days gained on large-scale production.

As your series grow, machine selection becomes critical. For efficient production, we recommend trusted industrial partners who can provide reliable support and spare parts for many years.

Finally, we strengthen your material supply chain by connecting you with reliable suppliers capable of supporting you on large volumes.

Custom Finishing Solutions: Machining & Surface Treatment

We know that surface quality is a critical requirement in additive manufacturing. At UBSIDE, we use two main strategies to improve the surface finish of your 3D printed parts:

1. Optimization of the as-printed surface finish

We adjust printing parameters and part design to achieve a smoother finish directly off the machine. This approach works well for single parts but may increase production time.

2. Post-processing & surface treatments

Depending on the desired finish, we provide various solutions such as mechanical or chemical polishing, precision machining.

Examples of finished parts we have produced:

- Tooling and molds for composite applications in aeronautics, drones, and foils: drilling, trimming, inspection, compaction, lamination.

- Grilles, trims, and MAPIEX components for automotive applications.

- Soluble tooling for manufacturing hollow bodies.

- Surfboards made from bio-based materials (PRDXL project).

- Battery housings in high-performance, flame-retardant materials (UL94 V0, high voltage resistant).

- Electronic supports and housings designed for outdoor and extreme conditions (UV resistance, water, high temperatures, RF shielding).

- Biodegradable parts for sports and leisure applications.

- Flexible parts and technical seals made of silicone.

Our added value

At UBSIDE, our teams master a wide range of additive manufacturing technologies and scales — from millimeter-sized parts to large-format components — thanks to equipment capable of reaching 4 m x 2 m x 1 m build volumes.

We offer expertise across multiple processes, including:

FDM printing

Granule extrusion (pellet-based 3D printing)

Continuous fiber placement

This versatility allows us to adapt manufacturing methods to your dimensions, material requirements, constraints, and ambitions.

Technical means

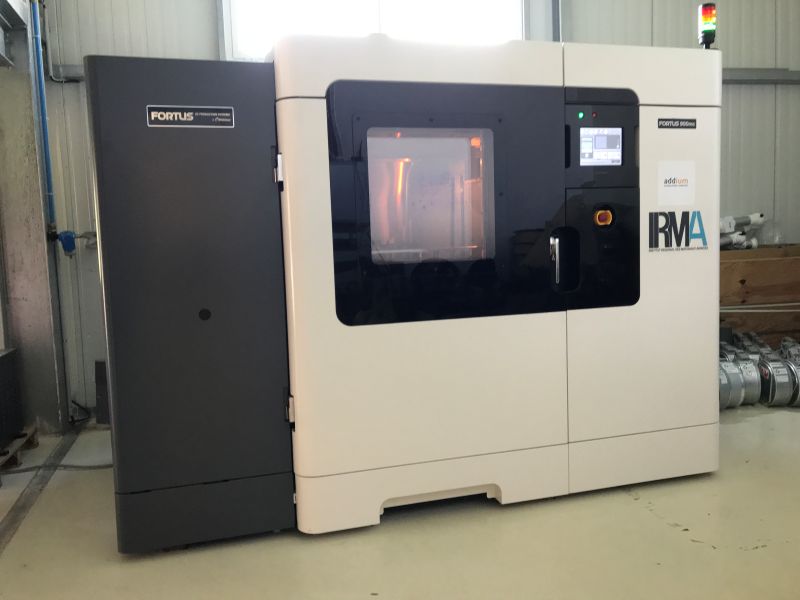

Stratasys Fortus 900mc:

an industrial-grade 3D printer for large, technical and high-performance parts, capable of processing high-temperature materials such as: PEI (Ultem); PC (Polycarbonate).

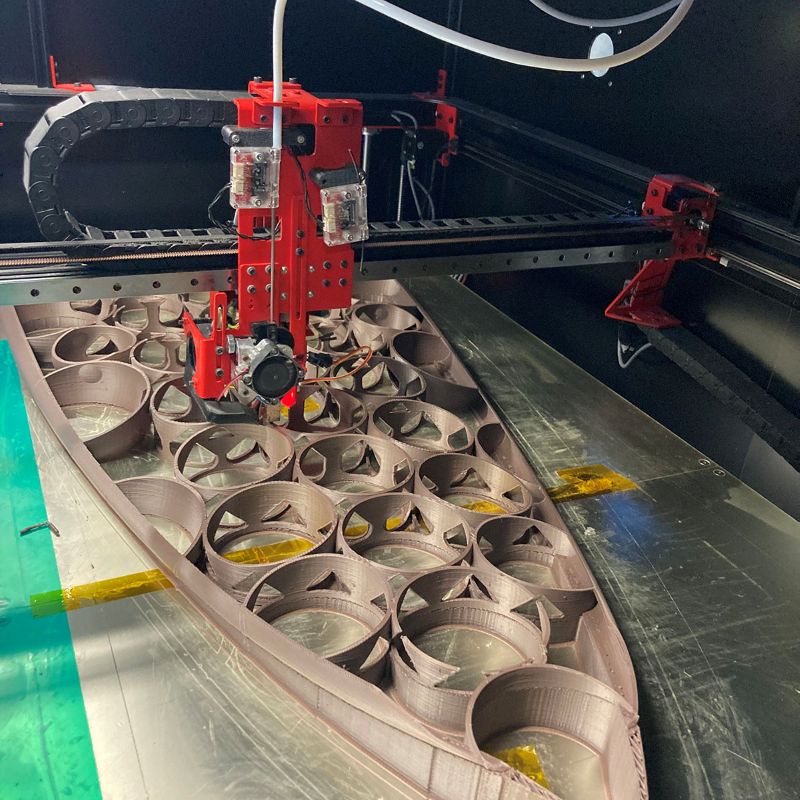

Modix BIG 60 & Modix BIG 120:

large-format 3D printers designed for oversized standard parts at competitive costs.

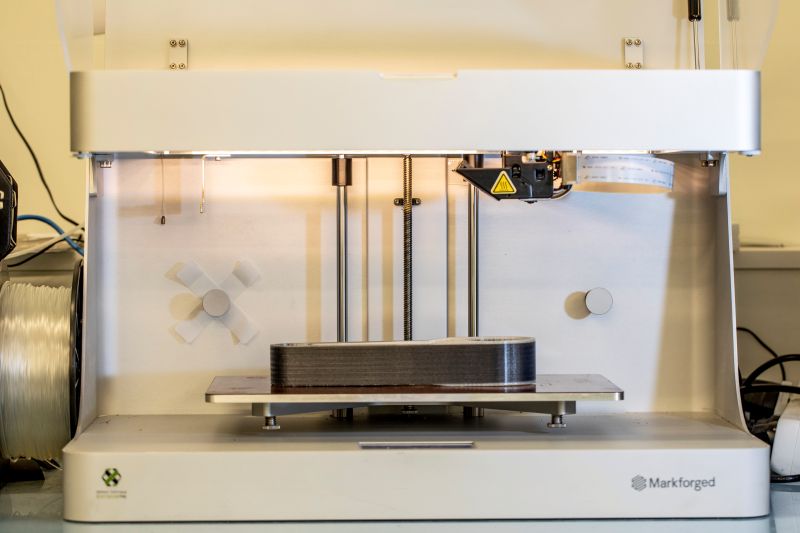

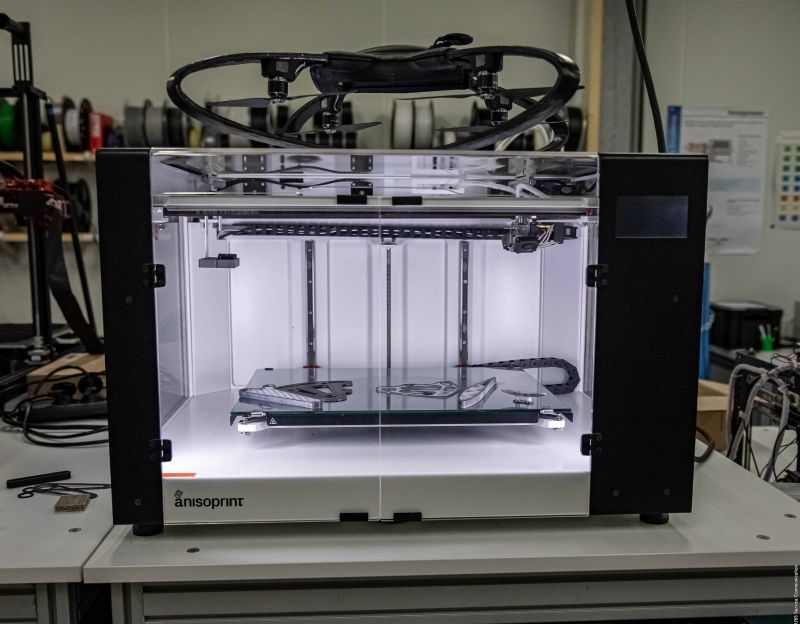

Markforged Mark Two and Anisoprint Composer A3:

a professional 3D printer designed to reinforce plastic parts with continuous fibers (carbon, aramid, glass)

Lynxter S600D:

designed for soft silicone parts, either mono- or bi-component, with Shore A hardness from 5 to 45.

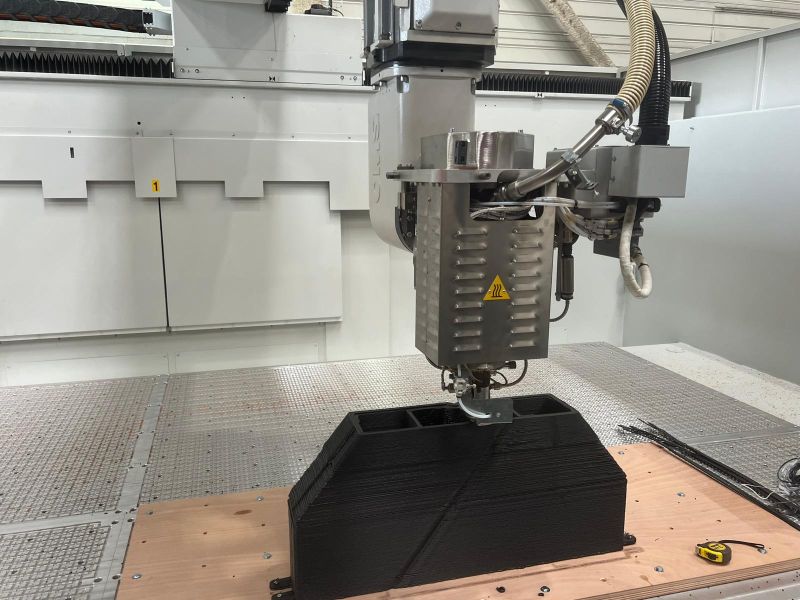

CMS Kreator:

a hybrid large-scale machine capable of producing parts up to 4 meters, with integrated CNC machining. Compatible with advanced reinforced materials such as: PEI-carbon; PC-carbon; ABS-carbon.

Open-source & desktop printer fleet:

perfect for rapid prototyping and small series production: Prusa XL; Prusa MK4 / MK4S; Zortrax M200 / M300; Creality…